A successful training is composed of different steps which allows us to deliver a recycling line with all the operating answers:

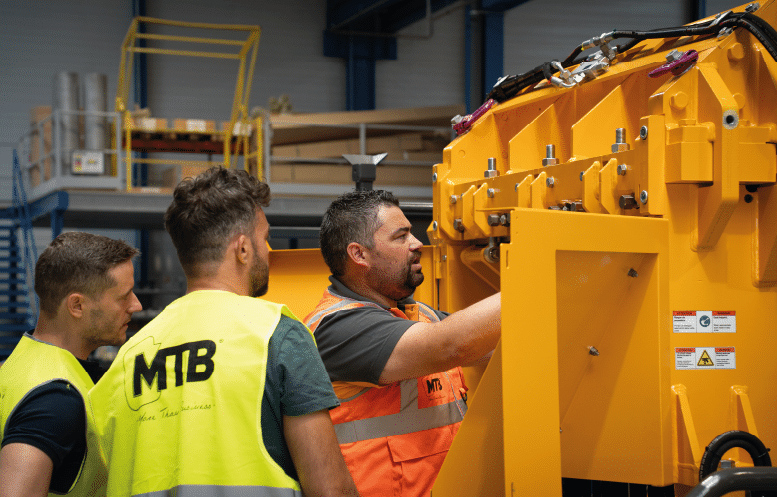

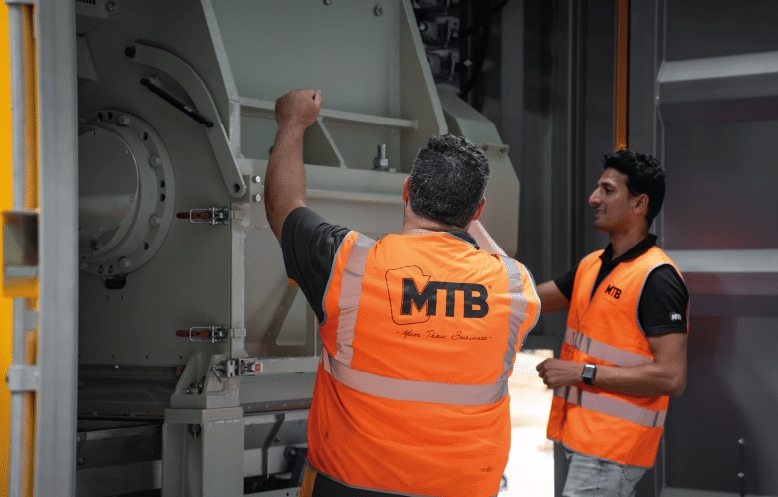

- Cold commissioning: All the equipment is tested step by step mechanically and electrically without material by our electronics and automation engineers assisted by our mechanical technicians (MTB service) and the project manager.

- Hot commissioning: That is the moment when our training and coaching technician join the rest of the team for testing line with material, correcting any possible problems detected and make sure the system is running at it should in terms of process before starting the initial.

- Initial training: Complete custom theoretical (in classroom watching videos of the customer’s equipment in operation) and hands on training about all the equipment, tutorial about PLC (programable logic controller), technical recommendations for optimal use of the line and finally let the operators running the system in autonomy the last day and answering all their questions during a final debriefing. The initial training allows you to use the production equipment at its optimal capacity in safe conditions and to take care of first and second level maintenance operations.