Actualités Recyclage

CO2 emissions avoided thanks to MTB processes

16 January 2025

Actualités Recyclage

16 January 2025

In order to contain the effects of climate disruption, international targets were adopted during COP 21, through the Paris Agreements in 2015. The signatory countries pledged to limit global warming of our planet to well below 2°C compared to the pre-industrial era, and preferably to limit the increase to 1.5°C.

To meet this commitment, France aims to achieve carbon neutrality by 2050.

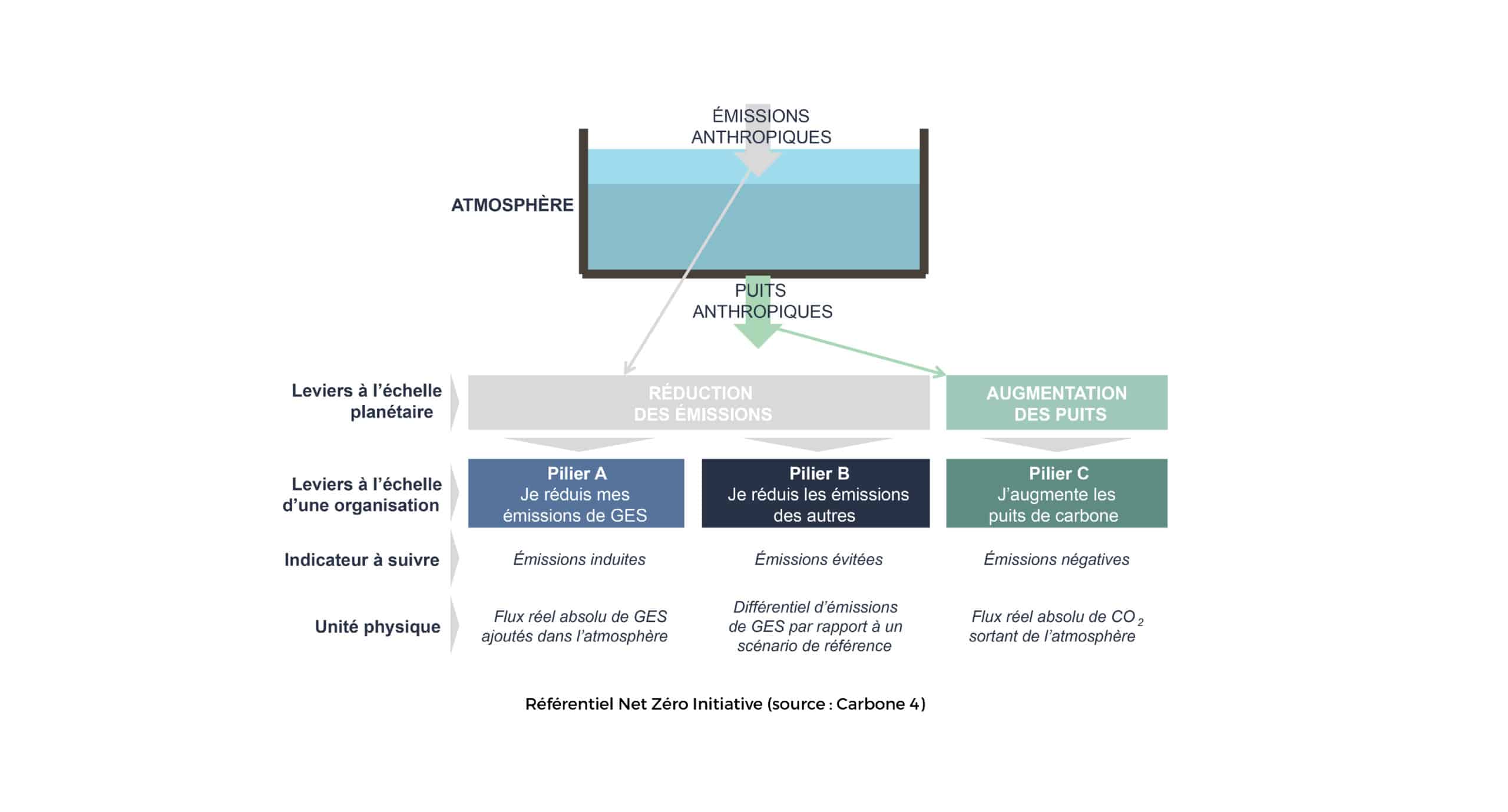

According to the NET ZERO INITIATIVE (NZI) framework developed by Carbone 4, an organization must act in three complementary ways to contribute to global carbon neutrality:

PINCIPLE A: Measure the direct and indirect GHG emissions associated with your business and take action to reduce them as much as possible across the value chain.

PINCIPLE B: Develop solutions and services to reduce GHG emissions outside its scope of activity

PINCIPLE C: Support carbon sequestration projects that contribute to achieving Net Zero 2050, meaning 0 net CO2 emissions worldwide by 2050.

Avoided emissions represent the emissions saved by the users of our solutions (principle B of the NZI guidelines).

It is essential that actions on each principle are treated individually. Under no circumstances can we subtract an organization’s avoided emissions (principle B) from its carbon footprint (principle A).

The methodology for calculating avoided emissions is based on comparison and subtraction between a reference situation and a situation with the solution.

1) The reference situation corresponds to the situation where the product or service does not exist.

2) The situation with the solution corresponds to the situation where the product or service exists for its entire lifespan.

The calculation of avoided emissions for a solution is carried out in three stages:

The definition of the reference situation represents a real challenge in the calculation: the assumptions chosen have a strong influence on the final result. The reference scenario must be representative of reality, and must represent the most likely situation in the absence of the sale of the solution. In addition, it is essential that the modeling is clear and transparent, to enable critical review by third parties.

The adaptation of the NZI methodology to MTB products was carried out in collaboration with Carbone 4 in 2023.

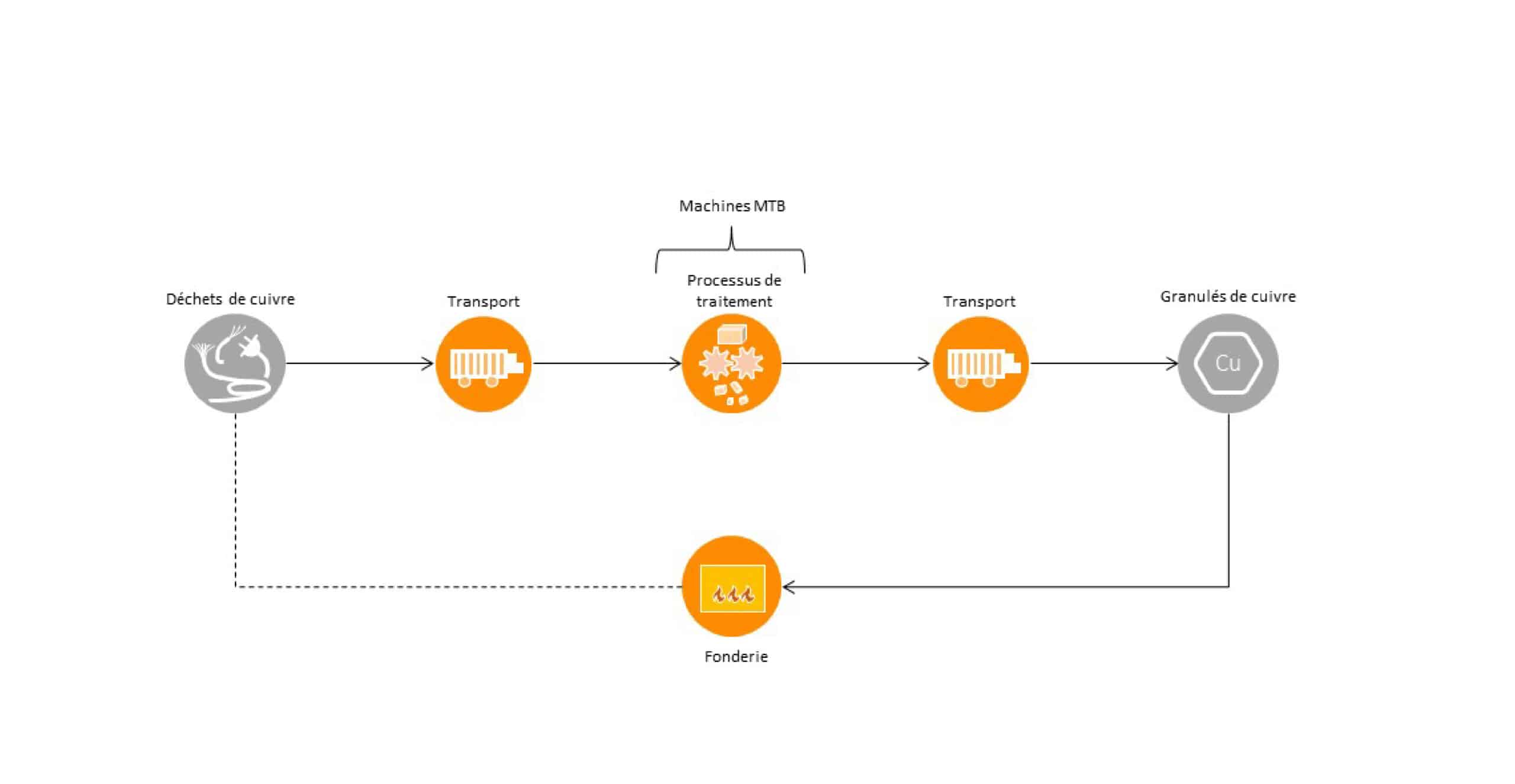

Each recycled raw material produced by MTB is different and requires an assessment tailored to its market characteristics. For the first calculations of avoided emissions, MTB has focused on recycling copper with a final purity of 99.9%. Throughout the following presentation, the term “recycled copper” will always refer to copper with a purity level of 99.9%. This recycled raw material (RRM) can replace virgin copper, given its physical properties, without further processing.

Considering MTB’s dual activity, it was necessary to choose 2 reference scenarios:

In both cases, the aim is to recycle copper with a final purity of 99.9%.

For the first reference scenario, it will be assumed that without MTB copper, a potential customer will buy commercially available copper.

Today, commercially available copper, whether recycled (30%) or new (70%), is produced and distributed worldwide. To assess the carbon impact of copper, we therefore need to consider the GHG emissions generated by the various operations involved in producing new and recycled copper on a global scale. The reference scenario for the recycling activity therefore corresponds to the average carbon intensity for obtaining the world’s copper stock (recycled and new).

For the second reference scenario, in connection with the manufacture of copper recycling machines, it has been considered that this activity contributes to global copper production and therefore to the decarbonization of the entire copper market. The average carbon intensity of the global copper stock (recycled and new) will also represent our reference scenario. However, as the machines only participate in one stage of the copper value chain, only part of the avoided emissions will be allocated to them through the use of an allocation key.

This allocation key corresponds to the proportion of the machine’s use emissions in relation to the total carbon footprint over its life cycle, i.e. 42% in our case. The allocation key is obtained by the ratio of GHG emissions emitted during the use phase to total GHG emissions over all stages of the life cycle.

Our machines are robust and repairable: they are considered to have a service life of at least 15 years.

MTB’s dual activity enables us to obtain data on machine use in the field. Thanks to this data, it is possible to get as close as possible to the performance of the machines in real-life customer conditions.

The CO2 emitted in the MTB scenario will vary above all according to the electricity mix used by customers in their country of location. Indeed, if the machine is installed in the United States, the carbon impact of its use will not be the same as if it were installed in France. In 2022, the machines were exported to several countries around the world. For each machine, the electricity mix of the country where it is installed has been taken into account. In addition, over the lifetime of the machine, the calculations take into account the electricity mix of the country where it is installed (IEA scenario).

The impact of collection is also taken into account: waste is assumed to travel an average of 500 km to the recycling site (MTB recycling site average).

For the copper cable recycling business, which produces 99.9% pure copper shot:

MTB Recycling’s production of 99.9%-pure copper shot in 2022, accounting for 70% of sales, has thus avoided emissions of

3,900 tonnes of co2 by 2022.

Calculation :

CO2 emissions in the reference scenario (i.e. the current state of the copper market without the MTB recycling activity)

–

CO2 emissions in the scenario with the solution (Trept copper recycling machine park)

=

Emissions avoided thanks to MTB copper recycling activity

For its business as a manufacturer of copper recycling solutions, achieving 99.9% purity and exported worldwide:

The machines, to be produced in 2022 for the production of recycled copper, which accounts for 60% of MTB Manufacturing’s sales, will make it possible to avoid emissions of greenhouse gases.

2.1 million tonnes of co2 over their lifetime.

Calculation :

CO2 emissions in the reference scenario (i.e. the current state of the copper market without the MTB recycling activity)

–

CO2 emissions in the scenario with the solution (our copper recycling machines installed at our customers’ sites worldwide)

=

Emissions avoided thanks to our activity as a manufacturer of copper recycling machines

Interestingly, with the advent of new technology and increasingly low-carbon electricity, we might have thought that virgin copper production would have less impact over the years, automatically reducing the emissions avoided by our 99.9% pure recycled copper. In reality, the production of virgin copper will be increasingly carbon-intensive, as we will have to dig ever deeper into the deposits to extract the metal (the copper content of the mines is decreasing).

Copper is an essential material for the ecological transition (production of electric cars, renewable energies, etc.). In the current context, it is estimated that demand for copper will continue to grow. Recycling is not the only solution to the problem of future supply: it is important to rethink our uses of this strategic material.

The results are very encouraging and give us a better understanding of the levers of MTB’s solutions to climate change.

MTB will continue to work on these means of action according to the NZI guidelines.

To reduce its CO2 impact (principle A), MTB must continue to work on its main emission sources as a matter of priority. To this end, we have set up working groups by emissions category.

In a second phase, avoided emissions will be calculated for the other recycled raw materials produced by MTB (aluminium, CSR, etc.) in order to have a robust order of magnitude.

And finally, in the midst of the metamorphosis of our recycling site, MTB is considering the implementation of carbon sequestration projects (principle C), with the co-benefit of reintroducing and preserving biodiversity within our industrial recycling site.