Équipements de recyclage Par Application Application

Équipements de recyclage Par Application Application

MTB Recycling offers specialized equipment for batteries recycling, covering all stages of the process from shredding to material separation.

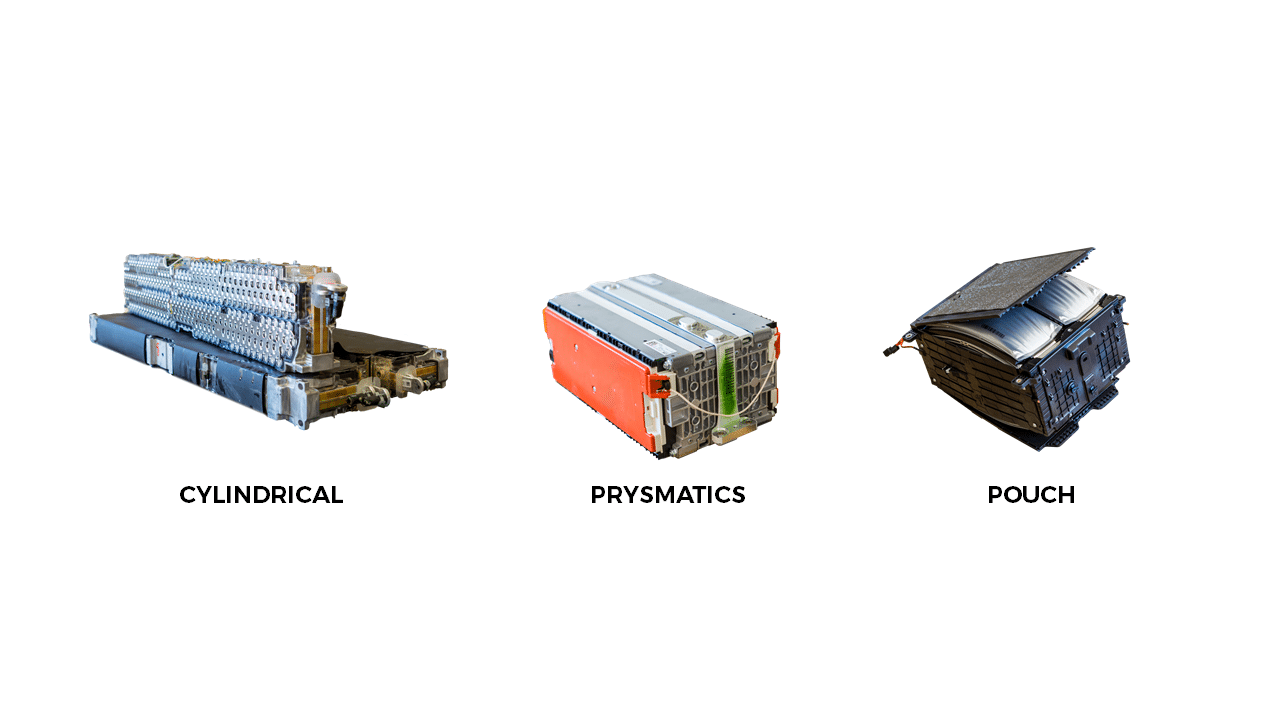

Our solutions can handle a wide range of lithium-ion batteries types, recovering valuable materials such as aluminum, copper and blackmass.

With advanced technologies, MTB ensures efficient, environmentally-friendly management of production scrap, adaptable to customers’ specific batteries recycling needs.

The discharged battery modules are shredded into fractions of less than 50 mm in the BVR 1200 shredder. The operation is carried out under nitrogen inerting with an oxygen content of less than 5%. The product is then conveyed to the evaporator to extract the electrolyte. An air treatment system treats incondensables and dust.

The dry product is sieved a first time to remove an initial blackmass. The remaining product then goes through an aeraulic sorting process to remove heavier materials, before passing through a densifier to break up the particles and release the blackmass.

Finally, the product is screened to recover the blackmass, and the remaining aluminum, copper and plastic foils are sorted on densimetric tables.

The operational equipment Drycell Box solves the problem of these first sources of waste. Its objective is to recover as much material from the anode, cathode and dry cells as possible. The recycling process is contained in a few containers for an easier and modular installation.